| Windmill Cables | |||

| EPR/HFXLEVA LSOH 0.6/1kV Torsion Resistant Power Cable |

![]() Windmill Cables

Windmill Cables

Application

These halogen free cables are used as drag chain cables for permanent flexible stresses in machineries, machines and tool building, robot systems, constantly moving machine components and multi-shift-operation.

Standards

UL AWM Style 20233

CSA AWM I/II A/B

Construction

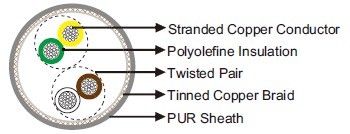

Conductor: Stranded bare copper, class 6 according to VDE 0295/BS 6360/IEC 60228.

Insulation: Polyolefin.

Screen: Tinned copper wire braid.

Sheath: Full polyurethane sheath TMPU.

Technical Data

Rated Voltage Uo/U (Um) |

350V |

Operating Temperatures |

flexing: -40℃~+80℃; fixed: -50℃~+80℃ |

Minimum Bending Radius |

flexing: 10×OD; fixed: 5×OD |

Flame Retardant |

VDE 0482-332-1-2/DIN EN 60332-1-2/IEC 60332-1 |

Halogen Free |

Yes |

Oil Resistant |

Yes |

Ozone Resistant |

Yes |

Silicone Free |

Yes |

UV Resistant |

Yes |

Abrasion Resistance |

Yes |

Dimensions and Weight

Construction |

Nominal Overall Diameter |

Nominal Weight |

No. of cores×mm² |

mm |

kg/km |

24AWG |

||

1×2×0.25 |

4.8 |

26 |

2×2×0.25 |

6.7 |

61 |

3×2×0.25 |

7.1 |

70 |

4×2×0.25 |

7.6 |

82 |

5×2×0.25 |

8.3 |

99 |

6×2×0.25 |

8.9 |

126 |

8×2×0.25 |

9.3 |

147 |

10×2×0.25 |

11.7 |

179 |

14×2×0.25 |

12.7 |

210 |

22AWG |

||

1×2×0.34 |

5.1 |

35 |

2×2×0.34 |

7.2 |

80 |

3×2×0.34 |

7.6 |

100 |

4×2×0.34 |

8.2 |

118 |

5×2×0.34 |

9.0 |

134 |

6×2×0.34 |

9.7 |

162 |

8×2×0.34 |

10.3 |

214 |

10×2×0.34 |

12.8 |

270 |

14×2×0.34 |

13.8 |

304 |

20AWG |

||

1×2×0.5 |

5.6 |

47 |

2×2×0.5 |

8.4 |

100 |

3×2×0.5 |

8.9 |

131 |

4×2×0.5 |

9.7 |

149 |

5×2×0.5 |

10.7 |

169 |

6×2×0.5 |

11.7 |

181 |

8×2×0.5 |

12.4 |

274 |

10×2×0.5 |

15.6 |

332 |

14×2×0.5 |

17.1 |

390 |

19AWG |

||

1×2×0.75 |

6.1 |

56 |

2×2×0.75 |

9.1 |

102 |

3×2×0.75 |

9.6 |

144 |

4×2×0.75 |

10.7 |

160 |

5×2×0.75 |

11.7 |

193 |

6×2×0.75 |

12.9 |

216 |

8×2×0.75 |

13.7 |

327 |

10×2×0.75 |

17.2 |

451 |

14×2×0.75 |

18.8 |

521 |

18AWG |

||

1×2×1 |

6.5 |

64 |

2×2×1 |

10.0 |

120 |

3×2×1 |

10.6 |

160 |

4×2×1 |

11.7 |

184 |

5×2×1 |

13.2 |

217 |